EGC-DL1000K/150 Model PLC Control High Speed Dry Laminating Machine, has the reasonable structure design, high precision processing and high speed production. At the same time, all the complete functions of the machine control system, a high degree of automation and programmable man-machine interface, together with PLC electronic components of high-quality, guarantee the machine quality and stability.

The control system of the machine adopts programmable control (machine tension, speed, and etc.), with PLC control system. Application of field bus network realizes the full auto control of the production process.

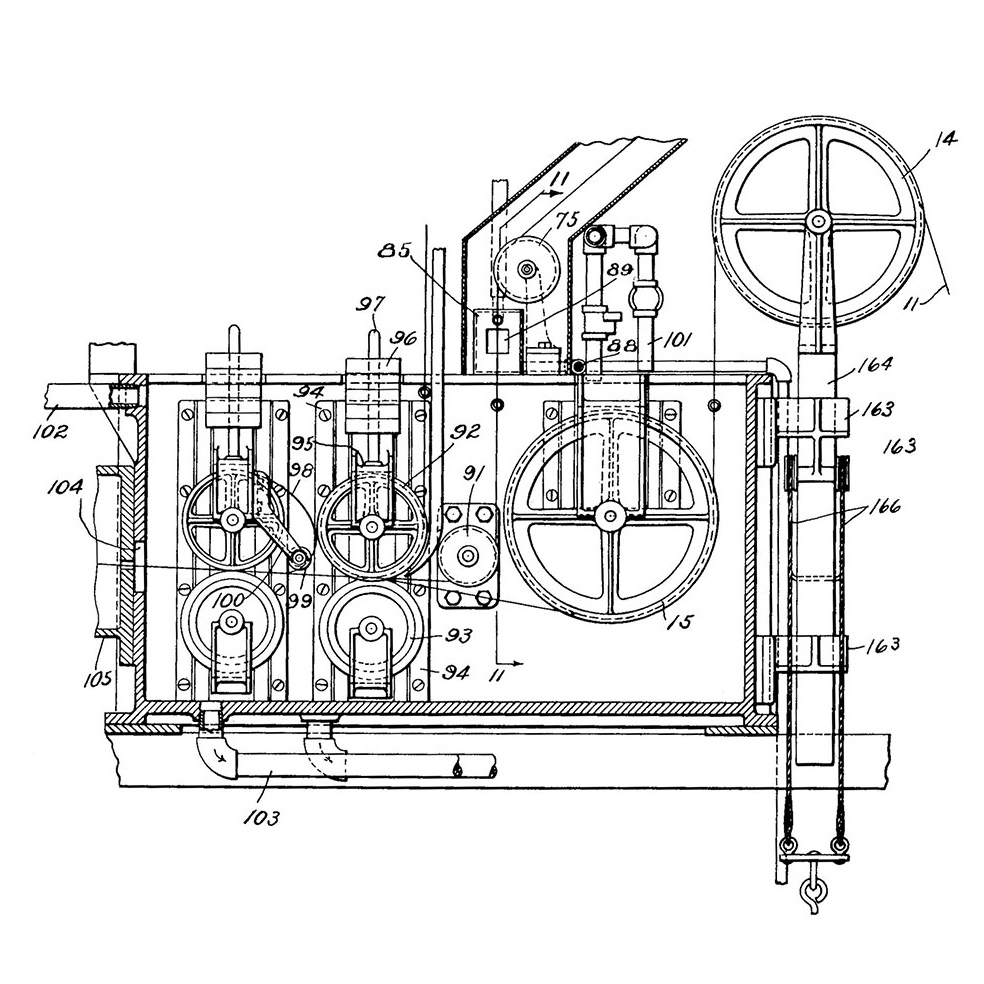

The three parts of glue coating, laminating and rewinding has advanced synchronous speed and tension configuration digital type AC frequency control system(variable frequency motor+frequency converter), and advanced tension full auto control. Glue spreading part is made up of anilox roller, pressing roller, blade in horizontal, glue recycling unit and etc. The glue spreading is driven by frequency conversion motor and controlled by AC variable frequency.

Drying oven: section heating, automatic temperature control, inlet/outlet air quantity adjusted according to the technology need. All the rollers in the oven drive automotively and synchronously.

Operating platform and handrail are installed at side of the drying oven for passing the film through the oven, with stairway.

Lamination part is made of laminating hot roller and good rubber roller with high temperature corrosion resistance. The laminating hot roller is driven by frequency conversion motor and controlled by AC variable frequency (during working, the tension auto detection and display).